HORIZONTAL SPLIT CASING PUMP

- INTRODUCTION

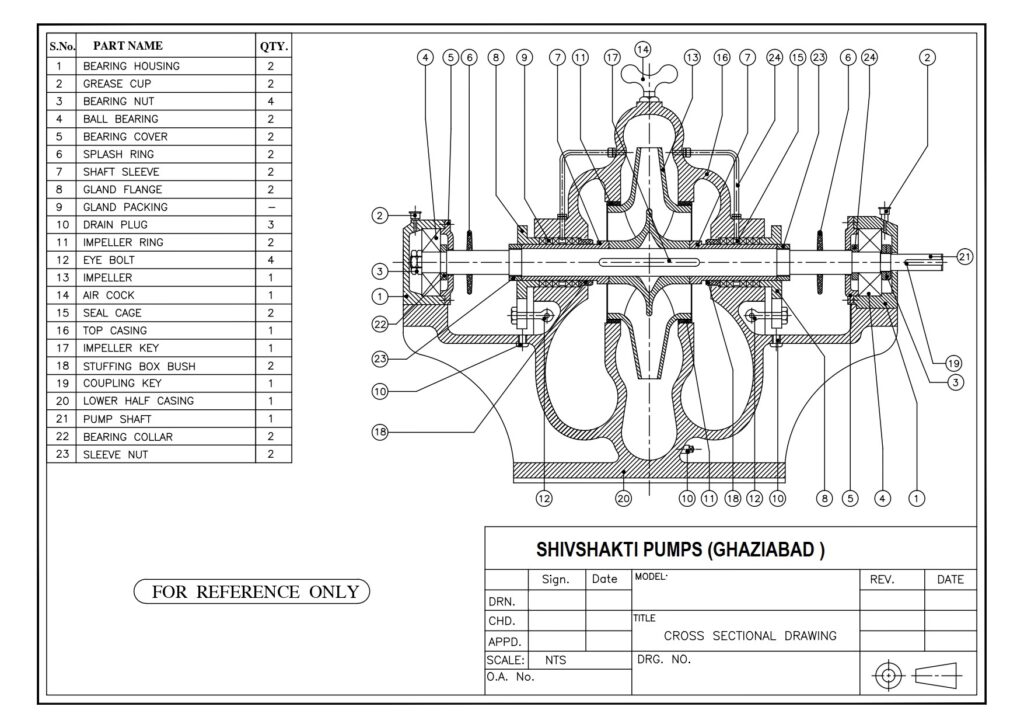

The SCS pumps are designed for specific capacity, speed, pressure and temperature. These pumps are manufactured to close tolerances and rigid specification each and every pump is tested at works for performance and trouble fee operation before dispatch. These are horizontal split casing type pump with suction and discharge nozzles and supporting feet integrally cast in the lower half casing. The construction enables to remove the rotating unit for inspection and repairs by just removing upper half casing, bearing caps and without disturbing alignment or pipe connection or prime mover. covered by these instructions. The pump when properly installed and given due care in operation and maintenance should operate satisfactorily for longer period. Our guarantee will be valid only if the installation, operation maintenance and repair of the pumps are carried out in accordance with our instructions.

Design Features

- CONSTRUCTIONAL FEATURES Casing:Axially split volute with suction and discharge branches located opposite inline in the lower half. This allows easy removal of the rotating element, without disturbing the pipe work. Pumps required for higher heads have double volute casing to minimum radial thrust. Flanges are drilled as per DIN 2543, 2533 ND‐16/ any standards.

Impeller: ‐ Single entry and double entry, closed type impellers are hydraulically and statically balanced.

Shaft: Machined from high quality steel. The shaft is sturdily proportioned to minimize deflection and provide long reliable service.

Sleeves: Sleeves are provided to protect the shaft and ensure longer shaft life.

NeckRing: ‐ Designed with appropriate clearances and materials to minimize leakages while ensuring a long impeller life. Improved Hydraulics: Unique hydraulic passage design for optimum performance. Stiff Shaft Design: ‐ Large diameter shaft supported on a short bearing span minimizes shaft deflection, prolonging seal and bearing life.

Simple Maintenance: ‐ Standard pumps cartridge bearings and seals can be removed without displacing top half casing. Increased Component Life: ‐ More corrosion allowance offers better corrosion protection and optimum lifetime operation. Enhanced Performance: ‐ Replaceable wear ring and bush reduce leakage. Increased Efficiency: ‐ Standard pumps coating on casing internals optimizes performance and prolongs “as new” efficiencies. Low Hydraulic

Loads: ‐ Diametrically opposed volute design reduces hydraulic loads extending seal and bearing life .

Parts Name | All Cast Iron | 02s Fitted | CF 8 Fitted | CF 8M Fitted | Bronze Fitted |

Volute Casing | Cast Iron | Cast Iron | CF 8 | CF 8M | Bronze |

Impeller | Cast Iron | CF 8 | CF 8 | CF 8M | Bronze |

Stuffing Box | Cast Iron | Cast Iron | CF 8 | CF 8M | Bronze |

Shaft | EN 8/SS 410 | SS 410 | SS 410 | SS 316 | SS 316 |

Sleeve | SS 410 | SS 410 | SS 410 | SS 316 | SS 316 |

Bearing Housing | Cast Iron | Cast Iron | Cast Iron | Cast Iron | Cast Iron |

Casing Wearing Ring | Bronze | Bronze | Bronze | Bronze | Bronze |

MATERIAL OF CONSTRUCTION

Other than above stated materials pumps are available in Cast Steel, CA 15, NI-Resist, Super Duplex, CN7M, Haste alloy and other special stainless steel alloys.